FDM 3D printer structure

- Categories:Company News

- Time of issue:2020-10-08 16:20

- Views:

(Summary description)Zhengzhou Chaokuo Electronic Technology Co., Ltd. was established in 2015. It is a cross-border e-commerce company dedicated to the research and development, production, sales and 3D printing technology solutions of 3D printer products. It has our overseas warehouses in the United States, Europe and Russia. , Our company's vision is "to be a world-renowned and respected company with the strongest employee happiness". Our mission is to "let personalized production capacity be given to everyone's desktop." The company has independent brands "flsun" and "Fusen"; flsun 3D printers are exported to the United States, Europe,Russia, South America, Southeast Asia and more than 150 countries and regions around the world provide users with creative solutions in the fields of industrial design, education, art, construction engineering and medical industries. The company provides one-stop 3D printing services, closely integrates 3D printing services with the Internet field, and plays an important role in building "individualized factories", building "individualized production", and realizing "individualized dreams". Among them, "QQ-S" printers have formed a huge user group at home and abroad, and maintained a good growth momentum. With good products, high-quality services and innovative Internet models, flsun Delta "QQ-S" 3D printers have a stable export volume. It is in the forefront of the industry and has been unanimously recognized by users and industry insiders all over the world.

FDM 3D printer structure

(Summary description)Zhengzhou Chaokuo Electronic Technology Co., Ltd. was established in 2015. It is a cross-border e-commerce company dedicated to the research and development, production, sales and 3D printing technology solutions of 3D printer products. It has our overseas warehouses in the United States, Europe and Russia. , Our company's vision is "to be a world-renowned and respected company with the strongest employee happiness". Our mission is to "let personalized production capacity be given to everyone's desktop."

The company has independent brands "flsun" and "Fusen"; flsun 3D printers are exported to the United States, Europe,Russia, South America, Southeast Asia and more than 150 countries and regions around the world provide users with creative solutions in the fields of industrial design, education, art, construction engineering and medical industries. The company provides one-stop 3D printing services, closely integrates 3D printing services with the Internet field, and plays an important role in building "individualized factories", building "individualized production", and realizing "individualized dreams".

Among them, "QQ-S" printers have formed a huge user group at home and abroad, and maintained a good growth momentum. With good products, high-quality services and innovative Internet models, flsun Delta "QQ-S" 3D printers have a stable export volume. It is in the forefront of the industry and has been unanimously recognized by users and industry insiders all over the world.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2020-10-08 16:20

- Views:

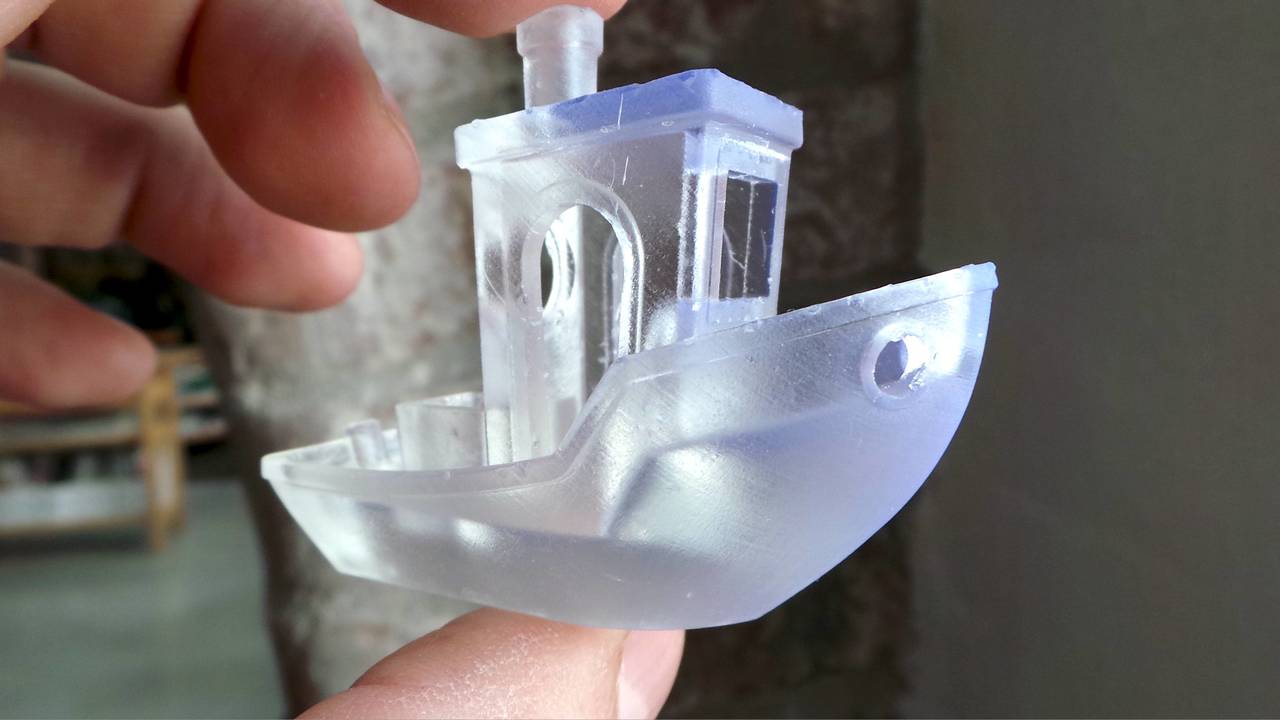

FDM (Fused Deposition Modeling) in 3D printing is a process fused deposition manufacturing (FDM) process developed by American scholar Scott Crump in 1988.

FDM materials are generally thermoplastic materials, such as wax, ABS, nylon, etc., which are supplied in filament form. The material is heated and melted in the nozzle. The nozzle moves along the part's cross-sectional contour and filling trajectory, and at the same time extrudes the molten material, the material solidifies rapidly and condenses with the surrounding material.

Advantages of FDM 3D printing:

1. Due to the simple structure and operation of the hot melt extrusion head system, the maintenance cost is low and the system is safe to operate;

2. The molding speed is slow, and the products produced by the fused deposition method do not need the scraper in the SLA to process this process;

3. Part prototypes formed with wax can be directly used for investment casting;

4. It can form parts of any degree of complexity, and is often used to form parts with very complicated cavities and holes;

5. There is no chemical change in the raw material during the molding process, and the warpage of the part is small;

6. High raw material utilization rate and long material life.

The structure of FDM 3d printers is classified according to the movement mode of each axis, which can be divided into the following models: RepRap, I3, DELTA, UM, MB, Core XY, the following is a detailed introduction.

1)RepRap

RepRap printers seem to be quite complicated, because the original intention of the designer is to make the machine copy itself, so it is hoped that each component can be obtained through 3d printing. Therefore, the support of polished rod frame structure is designed. In terms of practicability, this kind of frame structure firstly requires high assembly adjustment; secondly, the main components including the circuit board are exposed. Because of the stability of the square structure and difficulty in adjustment, the second-generation RepRap was changed to a triangular frame structure.

2)I3

The structure of the I3 3D printer is also known as the gantry architecture. This structure is relatively classic. It originated from the originator of the FDM 3D printer: RepRap. Because of its simple structure, easy-to-handle, and open hardware upgrade and maintenance, it is a favorite model for all major hobbyists. The 3D printing features of the I3 machine, the Y-axis printing is realized by the front and back movement of the platform, and the X-axis printing is realized by the motor driving the nozzle to move left and right. The characteristic of the i3 structure is that the movement of the Z axis is very stable. This type of model needs to pay attention to the stability of the frame, so it is generally not too large, and the printed model will shake when it is large.

3)DELTA

Delta is also called delta. Also called a parallel arm. This structure was first invented in the 1980s by Professor Reymond Clavel of the Lausanne Institute of Technology (EPFL) in Switzerland. The Delta parallel manipulator is a mechanical structure that controls the movement of the target on the X, Y and Z axes through a series of interconnected parallelograms. At the same cost, using the incremental type can design a larger print size 3D printer. The three-axis linkage structure makes it more efficient and faster. In addition, Delta 3D printers also have the ability to adapt to small spaces and work effectively in them. The structure is relatively simple, and the effect of printing curved surfaces is good. In recent years, it has been widely used.

The Delta 3D printer is a desktop mini 3D printer. Using it is equivalent to moving the industrial parallel manipulator to the desktop of an ordinary household. We can avoid the high cost of purchasing professional-grade 3D printers, and achieve 3D printing while ensuring accuracy and speed. But the DELTA model is prone to problems when printing rectangles. Low space utilization.

4)UM

The structure of the UM 3D printer is mainly embodied on the print head. It adopts a cross structure. The expansion motor is not at the nozzle end. It can effectively replace the weight of the 3D print head and increase the utilization rate of the internal space. The two optical axes are fixed. Because this structure is dual optical axis, it is more troublesome to replace some accessories, and it is relatively difficult to assemble.

5)MB

The structure of MB 3D printer is mainly embodied in the fact that the extrusion motor is generally installed next to the nozzle, the filament is fed in short distances, and the extrusion components are carried by the double optical bearing. The movement in the X direction is generally driven by the motor to drive the synchronous belt, and the two sides are moved together through the belt drive. Such a structure is relatively acceptable for filament feeding and 3D printing stability, but due to the X-axis timing belt transmission, it will limit the printing speed of the 3D printer. If the printing speed is too fast, it may cause loss of step. In addition, the extruded structure of the motor will increase the weight of the components. Attention should be paid to the replacement of consumables and maintenance operations to avoid deformation of the two optical axes.

6)Core XY

The difference between Core XY 3D printer structure and MB, UM and other structures is its transmission mode. The biggest feature of Core XY is that its X and Y motors work together, and its timing belt can be placed under different timing wheels. Form a variety of different winding methods. Due to the coordinated movement of the two motors, the force driven by the motor is greater than the force of a single motor, which will reduce the weight of one motor in the XY direction and improve accuracy. This structure has high printing accuracy, high speed and high utilization of assembly space. It is relatively complex, requires high assembly parts, and has a relatively large number of synchronous wheels or adapter belt bearings.

Each model has its own characteristics. With the development of the times, people believe that various models can use their advantages and avoid disadvantages, thereby bringing more happiness to 3D printing enthusiasts.

CONTACT US

TEl :

E-mail:

ADD :

Room 502 and 503, Building 6, Phase II, No. 27, Fenglin Road, High-tech Industrial Development Zone, Zhengzhou, Henan

Copyright © Zhengzhou Chaokuo Electronic Technology Co., Ltd All rights reserved. 豫ICP备2020034676号 Powered by www.300.cn Business License

Copyright © Zhengzhou Chaokuo Electronic Technology Co., Ltd All rights reserved.

豫ICP备2020034676号 Powered by www.300.cn